Got this email from Autodesk that Fusion is increasing their annual price by a huge amount. I subbed for 1 year a couple years ago for I think $380. Then I was able to get an educational sub after that. Fusion is still the cheapest CAD software out there, not including the free stuff like FreeCAD, but still, this price increase is massive.

It should be noted that it’s still free to use for personal use minus the extra features.

The problem is that there is no real competitor to fusion. If you think about usability/learning curve

Yeah, I’ve used multiple CAD tools, from pro/engineer to F360, but the learning curve of freecad felt like a brick wall.

I got stuck on googling how to make a fillet in freecad, to which the answer appeared to be, “yeah, nah, you sort of can’t”. Oh okay, this program is not for me.Edit: if people want to help/criticise, I recall the problem was that I couldn’t do it parametrically, which is the only way I like to model any engineering parts. So far the only thing that information has gotten me is a downvote. If freecad is as full featured as you say, then this should be easy to do. Feel free to tell me how.EDIT 2: after the info I got, I looked into it more and discovered my problem was a bit different - I couldn’t do a parametric offset line in a sketch, because I needed to make a particular pattern. I ended up doing it with OpenSCAD if I recall. I apologise for saying freecad couldn’t do fillets, that would’ve been extremely basic. It was still a very painful experience just to figure out that it couldn’t do what I needed.

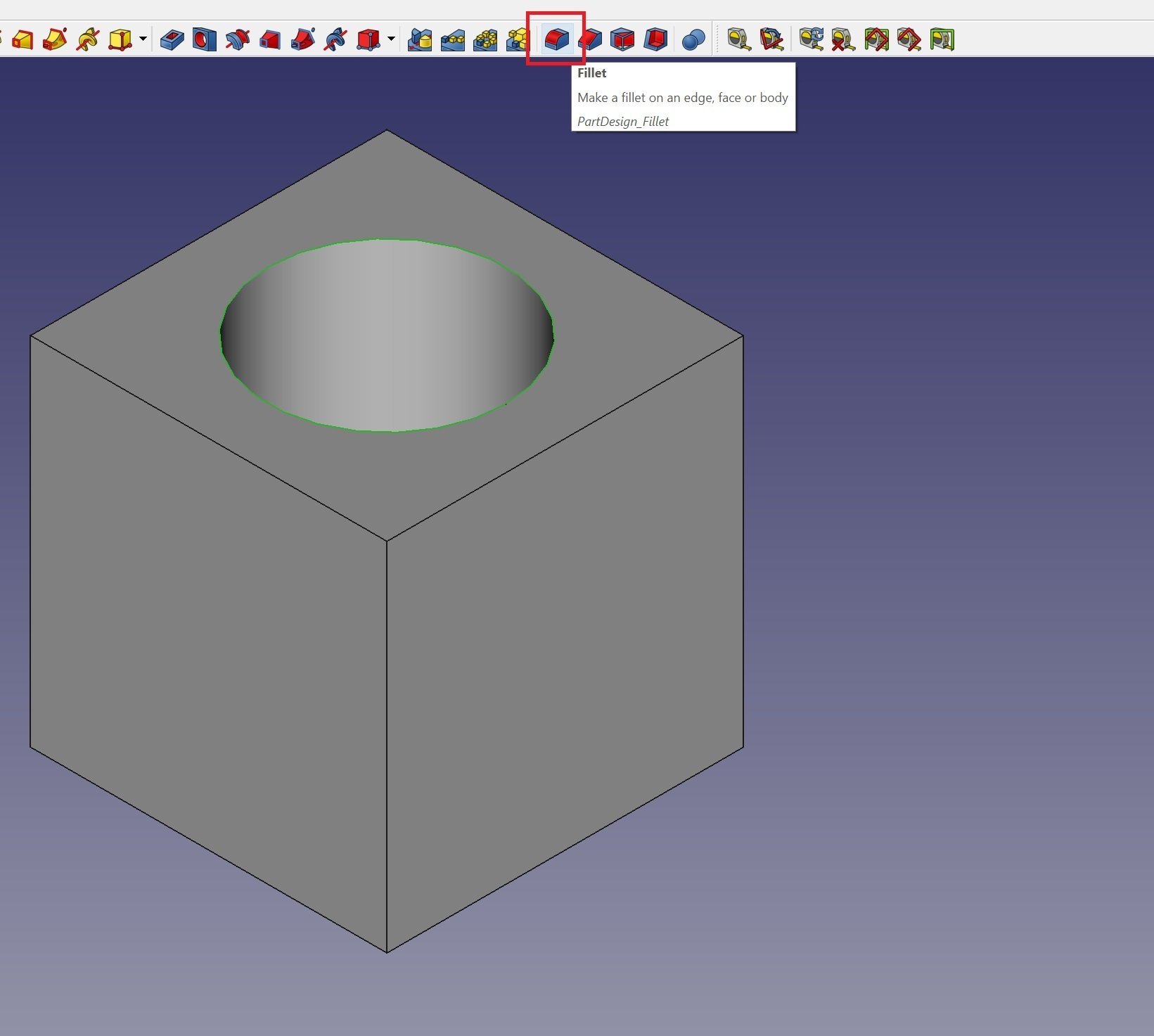

I don’t know how long ago you tired this (early versions were, even I will admit, kind of crap) but in the current FreeCAD release of 0.22.1 it’s incredibly easy.

Just select the edge(s) you want to fillet and and press the “fillet” button in the Part Design workbench…

And on the panel on the left you can set the radius. The profile of the Fillet tool is always a 90 arc of circle with the radius you’ve specified.

Or, if you want to get fancy and make your own bespoke custom fillet. Well, you can define its profile in a sketch. Here I just used a bezier to make an arbitrary curved shape. You are defining the profile of the material you want removed here, i.e. the negative space. You can make this as mathematically rigorous and precise as you like.

Then, position it somewhere on the vertex you want to profile and once again in the Part Design workbench, select that sketch, and hit “subtractive pipe.”

From there, you can hit “add edge” to define which edge(s) you want it applied to. You get a preview of the material removed.

Et voila.

I appreciate all the effort you went to, and I can do this as it turns out. Now that I’ve researched what problem I was having, it turns out the issue was that I couldn’t do a parametric offset line in a sketch, which was crucial to what I was doing at the time, so I had to give up on it.

I was using 0.19 at the time, because that’s what I’ve got installed.

whens the last time you used freecad? theres literally a button for making fillets.

I honestly forget, it was such a terrible experience I didn’t give it any more time. I think that the problem was that I couldn’t make it parametric.

I tried using Freecad as to filet something recently and it told me to look at the error console for more information, after googling for where the error console is, I realized the message to look at the error console was being output to the error console.

There was no more information to be had. It is a UX and functional nightmare, and it is what it is, but the downside is this means millions of engineers are being trained on subscription web sites, and eventually this will be used to both squeeze people for money, and also to prevent people from creating unauthorized or patented parts.

Onshape has replaced fusion for me, was an easy switch.

Isn’t onshape for non-commercial only?

Non-commercial is the free version, with all your parts public.

They also have a pro license with a fee, where your parts are then private obviously.

The pro license is like $2000 per year.

No, no - they’re not raising the price; they’re rebalancing it to reflect the value it delivers!!1!

And since they’ve reduced the free version functionality significantly, I believe I’m due a substantial rebate.

I’m sticking to FreeCAD.

It’s such a bad piece of software I just don’t get how people can use it…

It’s one of the biggest problems of the whole 3d printing ecosystem that so many people are relying on software like fusion or tinkercad that could shut down, lose its free option, and see massive price increases on subscription software.

I wish I could wrap my head around freecad, but we’re just not there yet and we may never be. I feel like it or something like it must be our future because until we have a full libre software chain we’re living on borrowed time.

I wish I could wrap my head around freecad, but we’re just not there yet and we may never be.

May I ask why it is that you say this?

I also have this question. What is so different about the workflow between FreeCAD and other 3D CAD software? If you can do one, you can do the others.

The learning curve is steeper mostly due to tools not having as intuitive names and ui layout.

I dove into fusion 360 last year and was making functional and nice parts within the first couple of hours. Since moving to Linux I’ve tried freecad and while I can eventually find the tools that do the same things, it is less intuitive to get there.

Additionally, when I run into a roadblock in fusion 360, I can usually find quick and easy explanations or tutorials for it, and just have not had the same luck with freecad. I can usually get the hurdle crossed with the tutorials but I find I have to look up the same stuff often as it doesn’t stick.

This is all nebulous as all hell, I admit. And I can vaguely tell that it does all the same things similarly to fusion 360, but it’s just different and obscured enough that I feel useless and obtuse using it and spend more time searching for tutorials and answers than I do designing.

I want to learn it. I want to use it. But I still find myself in fusion 360 when I need to get a part designed sooner rather than later - it took less effort and faffing around to get fusion 360 working in proton ge than getting to a stable point using freecad.

FreeCAD is a strange mix of over-designed and unfinished.

There’s like three different workflows for doing parametric CAD, plus a drafting workflow for an AutoCAD architectural experience, plus workbenches for meshes, NURBS, etc. Occasionally a tool you need will be in another workbench. There is no official assembly workbench included. It’s not exactly obvious how workbenches work together. A lot of shortcuts which have become Just How You Do Things in other CAD software aren’t present, so you have to do things an awkward long way. Add-ons and macros can help…but are poorly documented if at all.

Uhm, what about Blender?

blender can be used as cad software, but for any practical application, you want parametric design.

Blender is not designed as a CAD software. It is for 3d modeling. So you would use Blender to make graphics for a video game, or a 3d movie.

CAD is more for designing things to be made outside of a computer, so 3d printing, CNC or stuff like that.

Blender doesn’t consider the object as a whole, and can leave holes that a CAD setup would handle.

You can still use blender though if you know how to model in it already. Just don’t leave holes and you will be fine. I use that for a lot of 3d prints I make just because I am already comfortable with it.